Datasette modification

Contents

Ward Shrake's Datasette to Datasette modification

(This is a slightly edited version of an article originally available on Ward Shrake's now defunct "Digital Archaeology" website)

One specific bit of hardware that I craved [in the early 1980s] was a black box that was used to make perfect copies of tape software, with almost no work on the user's part. As hardware goes, its design was very elegant, even if its circuitry was home-made. I couldn't forget how cool it was. I always wanted one, if only as a background want.

That desire eventually forced me to figure out how to make one myself. I know how to make one now. With some encouragement and help from folks on the Internet, I figured out how to take a standard Commodore C2N datasette, modify it internally, and have it not only do its routine job as a datasette, but also act as a digital software archiving tool. (A special thanks to John Henkle, who first figured out the internal pinouts info needed.)

It looks and acts just like a datasette would, except that it has a hole in the front of its case where you can plug in a second datasette. With one modified and one standard datasette, you can make accurate digital copies of old tape programs, simply by hitting "play" on the first machine and "record" on the second machine. It makes its copy as it loads the original into the computer! You just can't get much more user-friendly!

What really makes this modification cool (IMHO) is that it uses zero parts. A few cut traces on the PC board inside, a few jumper wires, some solder, and a hole cut in the front of the datasette's plastic case. That's it. Not a single chip added, nothing taken out of the original device that will affect the way it works under "normal" circumstances. The only real external clue that the tape drive is modified would be the new hole made. If the theory of how this all works interests you, read about it here. (If not, no biggie.)

Detailed step-by-step instructions

This project involves modifications to a factory-made circuit board. It is not terribly difficult if you have had a moderate amount of experience with that sort of thing. Good soldering skills are a must. I can show you where to cut traces, where to solder jumpers from one circuit board trace to another one. I can even give tips on how to do it, as I go. But ultimately quality control is completely beyond my control. As far as any sort of electronics projects goes, only you know for sure if you should give it a try or not. As with any such project, messing up a peripheral device may hurt its host computer, too.

It is assumed that the person who ends up doing this modification already has enough skill with electronics and is comfortable following diagrams and written instructions. If that is not you, please find a friend who does have those skills and can help you out! What parts do I need to do this project?

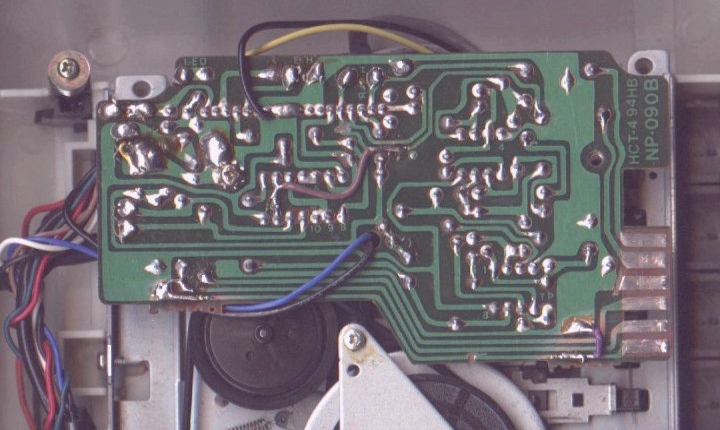

First off, you have to have a datasette to modify. Specifically, a C2N model that has a circuit board just like the one shown in the diagrams above. (Model NP-090B.)

More than one model was made; the only sure way to know what is inside the one you have is to open up your datasette and look inside it. If you have the circuit board just like the one shown here, you are in luck. Feel free to jump ahead to the next step.

If you find that your circuit board model differs from the one shown, you can quit now or move onward on your own. Doing the latter assumes that you have the technical skill to read schematics and so on. It also assumes you can look at what was done to this circuit board and mentally figure out how to make functionally similar necessary changes to accommodate a different model of PC board than this one. If you go this route, you'll want to read the theory of operation section to figure out what I did here and why I did it that way. (No luck? Maybe a friend can help you, if you give them this information and a "motivating factor" known in most hobbyist tech circles as "a few cold ones"?)

What tools do I need to do this project?

I am assuming you have a soldering iron handy; a 15-watter would be fine. Avoid high wattage irons for the usual reasons; circuit board traces are essentially just copper foil glued to a fiberglass board. (Too much heat lifts these delicate circuitry traces right off of the board and ruins the entire device, perhaps beyond easy or economical repair. If you know what you are doing, fine. If not, again, find someone who does and bribe them!)

Besides an appropriate soldering iron and the skill to use it safely, you will need just the basic hand tools used in any electronics projects. Wire cutters and strippers. Some small gauge wiring, to be used in a few places as jumpers. Maybe some desoldering braid. A Phillips screwdriver to take the plastic case apart. You may need a tiny Phillips to get at one pesky screw underneath the circuit board itself; a sharp point on a regular Phillips may work, but don't take a chance of stripping that tiny screw head, either.

You will need some way to cut a few circuit board traces. For myself, I use a very small ball cutter in a high speed Dremel motor tool to cut traces. It gives me excellent control and makes precise cuts. This is important so that you don't cut traces you don't intend to. But some people use a sharp new blade in an X-acto style hobby knife instead.

I do use a rounded X-acto blade to do some preliminary scraping over circuit traces before trying to solder to them. I usually touch that up with some of that incredibly fine sandpaper found either in Testors model kit sanding packs or in most generic cartridge port cleaning kits sold for NES systems or whatever. ("Toy R Us" likely has both.)

Some method of cutting a square hole into the case of your datasette will be needed. I will leave the exact method up to you; I used a Dremel tool again. And some small files.

A well-lit, clutter-free work space is also helpful. As is some sort of magnifying glass, so that you don't go blind trying to see all that tiny circuitry close up. You will want to make sure you've connected things to the right places, that circuit traces really are completely cut and make no connection, etc. A multimeter comes in handy for that sort of stuff.

One last thing; there are some colors I used to code a few things in my diagrams. I do appreciate that some folks have varying levels of color blindness. I kept the colors to a minimum just in case. I only used three colors; mostly two, really. (Have a friend help?)

Let's get started, fer crying out loud!

OK. Assuming you have detached the datasette from the computer first, second you should open the plastic case up. There are four screws on the bottom. Unscrew each of them. Take the bottom of the datasette's plastic case off and flip it over. You can use it as a tray as you work; to hold screws and such, so that you don't lose them.

(Keep in mind that we're dealing with a specific model datasette as we move on. If your model differs you'll have to figure out how to adapt on your own, as previously stated.)

There should be a chrome-looking shield over the main circuit board. On mine, only one screw held the shield itself down, although one other holds the main circuit board in. (Two screws total.) Unscrew them both and put them aside. Put the shield aside also.

The main circuit board has a number of wires running to it from all sides. On mine there was a central hole with two wires (blue and black) running through it. This led to a tiny leaf switch located underneath the board itself. That wiring is probably tight. Take care when bending the circuit board back or sideways. Be gentle and check things out first.

The tiny leaf switch should be temporarily unscrewed. Either at an angle with a large-ish screwdriver or through the hole in the PC board with a tiny screwdriver, take out the single tiny screw holding that leaf switch in. Put that screw someplace it won't be lost. Cutting a few circuit pathways....

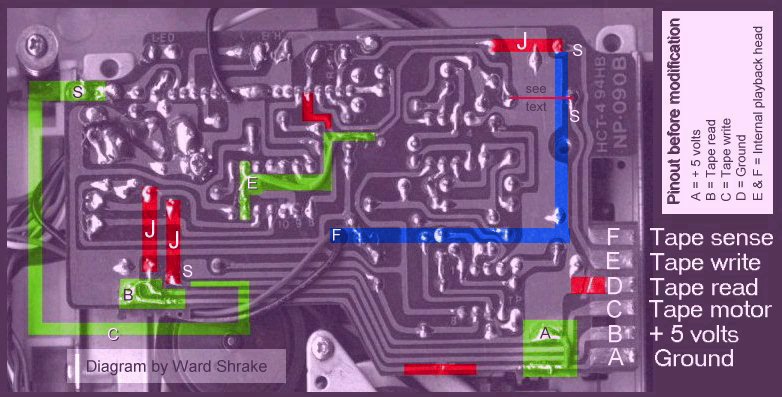

You should study the color-coded circuit diagram I've included here. It will tell you most of what you need to do and where you need to do it. Refer to it as often as needed.

There are six places you need to break the circuit pathways for this modification to work. You may note that there are six output pins on the circuit board's inner connector. (Where we are going to plug the second datasette into the first one; here is a picture of the cable plugged into it later on.) The number six here twice is not a coincidence.

Every one of the six output pins on the connector is completely wrong for our purposes at this point. What you are going to do first is remove all of the old electrical signals that once went to those pins. Then we can replace them with the signals we want. The red boxes in the diagram represent the exact circuit board traces that need to be cut. (For now just ignore the thin red line that looks different than the much wider red stripes.)

To make things as simple and as elegant as I could, I took the time to see if there were any easy ways to eliminate these circuits. (Not everyone is very comfortable cutting PC board traces.) As it turns out, three of the six can be cut very simply. The red boxes I labeled with a "J" are ones that have jumper wires on the other side of the circuit board. Those are much easier to cut than circuit board traces. Find the right jumper wires and cut them in two, on the reverse side of the circuit board. Wire snippers should work. Spread the two ends of each broken jumper wire apart a bit so they no longer touch.

The next ones are unfortunately somewhat harder. (Here's that diagram again.) The two in the bottom right hand corner of the diagram are the next easiest to cut. Just look at the diagram closely and cut where I cut. (Here's what the finished board looks like.) If it makes you feel any better, the circuit that once led to pin "D" won't be used again. You do need to cut it, however, as right now it is connected to the circuit's electrical ground.

The next one is a pain, if you do it the way I did it. I cut the circuit trace where the red boxes indicate; it looks like an "L" with another short turn in it? See it? I cut the trace there and attached a short jumper wire just to the right side of that cut. (In a moment.) If you figure it out instantly and like the way I did it, great. If not, use the alternate method.

It isn't quite as pretty, perhaps, but it should work out just as well, electrically speaking. (Your choice? I realize I'm accommodating varying degrees of reader's skill so I am trying to offer alternatives. Do it either way you feel comfortable doing it is the bottom line.)

If you follow that circuit pathway with your eyes for a moment, you will see that it ends up in another one of those easy-to-cut jumpers on the reverse side of the circuit board. See it? Just before it turns downward and ends up at pin "E" on the connector?

If you want to do it an easier way than I did, cut the jumper that corresponds to the thin red line I made between those two solder joints, towards the upper right hand corner of the diagram. (It is the one that is labeled "see text" and looks different from the others.) A bit of desoldering....

Take another look at that colored diagram. This time you are looking for four places where I have placed the letter "S" on the drawing. These are places that will soon need jumper wires attached to them. Two of these spots are right at the point where you cut a jumper a moment ago; three of them, if you used the alternate method that involves the "see text" line. The fourth is towards the top left of the diagram. Find them on the board.

On my board, there was already an open hole at the fourth spot. I lucked out. Yours could be buried under a solder blob; no way to tell until you look on your board. (For the sake of simplicity I am going to assume from now on that you took the alternate way of cutting the "see text" line in the step above and explain things for that method only. The other way was advanced enough that if it didn't make sense already, just ignore it.)

What you want to do at this point is to get those spots ready for a wire to be attached there. The three that have half a jumper wire each in them should be easy enough. Heat the solder on top while gently pulling on the wire fragment from below. This will pop the wire out of the hole, but may leave bits of solder covering the hole itself. You can clean up these holes with some desoldering braid, or a solder sucker if you prefer that.

Do whatever you have to on the fourth spot, but don't disconnect the wires that are already there. You just need one more wire to fit somewhere in that same spot. Connecting the "tape motor" jumper wire

The first jumper wire connects up our new "C" pin on the output connector. Get a few inches of some relatively small gauge wire, similar in size to the wires coming in from the main cable that runs out to the computer itself. The fatter the better within reason. One end of this wire goes into the hole marked "S" near the top left on the diagram.

The other end of the wire ends up following the green "C" line until it hits the hole you just cleaned out at point "S" on the other end. (That should make sense, I hope?) Do keep in mind that the top hole is fairly huge blob of solder; watch out for cold solder joints when you attach the new wire. (The path for the new wire can be more direct and shorter than the way I drew it; that was just to keep things clear in the drawing itself.)

Congratulations, the "Tape motor" pathway is now properly hooked up. Without this line, your second tape player's motor will not turn. That's definitely a major problem! (Including remarks like this may help trouble-shooting, if it does not work properly.) Connecting the "tape write" jumper wire

Take another look at the diagram. See the green squiggly line with the letter "E" on it? Towards the center of the diagram? That is where we need to attach the next line; at the "E" that I marked. There should be a straight line on the circuit board between pins 2 and 13 on the chip we are dealing with at this point in the circuit.

See the other picture for clarity. First find the small pin numbers Commodore already labeled. Count them off from right to left; pin 8, then 9, then 10, 11, 12 and finally 13. Stop there. Moving directly upwards from that pin should be a circuit board trace. It connects to a pin on the other side of the chip. As it turns out, that other pin is pin 2.

This is where we are tapping off of the "second-to-the-last" inversion stage, before the normal circuitry hands the cleaned-up signal to the computer. We left those lines alone so that the datasette still works normally when we want it to. But we want that output connector to feed the second datasette, don't we? So the signal has to go from pins 2 and 13 of the 74LS14 (hex inverter) chip, across a jumper wire, to pin "E" on the output connector. If you trace that line (from the connector going backwards) you will see that right now it dead-ends at an open solder hole. Which makes at least one end easy.

So you need a wire long enough to reach between that open solder point and a place on the top side of the circuit board. Which is where the problems begin. You can't solder to the green stuff that covers the circuit board traces. Solder is made not to stick to it.

To be able to solder the new wire you are adding to the point near pins 2 and 13 you have to carefully remove that green stuff to get down to the bare copper foil. But if you go ballistic and are careless, you will destroy the delicate foil under the green stuff. And you do not have a lot of room to work with, either. There is no better place, however.

If you already know how to go about this, jump ahead to the next step. If not, next up is my method of going about this. It does work, it is relatively safe, but it takes some care and some patience. Not to mention a steady hand and a good eye; no "cold ones" now!

Assuming you finished this step up, we'll move right along. You should have two of the new lines hooked up now: the line that powers the motor and the new output line. How to prep circuit board traces for soldering

Assuming you have the tools and stuff I specified early on, you first take the rounded X-acto blade and you carefully scrape off the top layer of green stuff. This will get it visibly clean, but not electrically so. Enough of it will remain to make solder sticking to it nearly impossible. This is what that ridiculously fine sandpaper is for; final preparation.

To scrape the PC board safely, pretend the X-acto knife is a putty knife. That's the simplest way I can describe my method. You are holding the knife itself at roughly a 45 degree angle to the circuit board, with the blade pointed away from your body. The blade is at right angles to the trace you are working on. Gently pull backwards.

I want to make it perfectly clear that you should avoid anything that would scratch the trace or put too much direct pressure on any one small area of it. That is one reason I like the large, rounded style of blades; more surface area means fewer trouble spots later, both in terms of scraping more green stuff off and in avoiding circuit damage.

You are only looking to remove the green stuff over a small area. Maybe a quarter inch long and as wide as that one trace is. No more than that is really necessary once your soldering skills are good enough for consistent work on circuit boards like these. (I will not even mention modern surface mount boards, with all the ultra-tiny parts they have!)

Using the knife does get most of the green stuff off. And you can easily control the exact are you want to deal with. It is when you get to the final prep stage, with the sandpaper, when things get a little harder to control. Try this trick; it makes things much simpler.

I have a set of small files in my toolkit. Besides being handy for jobs that require files, the back ends of the files have a long, flat dowel shape that is handy. I cut a thin slice of that special sandpaper to the approximate diameter of the file's back end. (It would be the "tang" area, if they were normal-sized files with wooden handles.) I make it maybe two or three inches long. I wrap the sandpaper along the files "tang" long-wise; in other words, down one side, across the bottom and back up the other side. What I end up with is a sanding block that covers only a very small surface area. Perfect for this use.

The end result you want is a bare copper foil where you want it, surrounded by green stuff everywhere else. This helps cut the number of traces that end up touching each other on accident , electrically speaking, when you start soldering to the traces later on.

All I can say, if you have never done it before, is be careful! Better yet, go get some bit of circuitry you could not care less about and practice on it first. Practice up first. When you can consistently add a small dab of solder to a bare foil trace and have it stick with no problems with only a second or two of heat applied to the board, you've got it down.

One further tip: use the smallest diameter solder you can find. Radio Shack sells some stuff I love; it is a small spool of 0.022 diameter solder. Almost thread thin. This makes it much easier to control the amount of solder you put anywhere. If circuit board work drives you nuts right now, and you use that eighth inch thick solder, buy a spool today! Connecting power and ground

If you got through the "tape write" line OK, next comes two similar lines. Both of them have already been disconnected from the incorrect signals they once were. Now they need to be hooked up correctly. This should only take two short jumper wires.

Both of these require modifications to the printed circuit board's green stuff in a couple of places. This is needed once again so that you can solder wires to the copper foil. This time it is not quite so bad, because you are not so constricted, space-wise. I chose to put my jumpers at the green-colored areas I labeled "A" (for ground) and "B" for the power (+ 5 volts) connection. These were not the only available spots, but they'll do.

The diagram will once again show you were and how to connect things. You can also see the full color diagram of the finished circuit board; that may make things clearer.

You may notice in the full color version that I sanded off too much of the adjacent green stuff. (Especially near area "A".) Shame on me; I just got too impatient when I sanded; I used my finger. It didn't hurt anything that time, but it is not a good practice to get into. Connecting the "tape sense" and "tape read" jumper wires

Back to the diagram again. See the only blue line there? You may as well do that one next, because there are no others left! What happened to the "tape read" line? That one is not hooked up to the output connector at all. What it does in a normal application is to act as the line coming from the datasette to the computer. Although we want data to flow in both directions from the first datasette, we only want traffic going one way to the second datasette. It would not make sense to have the second datasette sending any signals back to the first datasette, so we just left the "tape read" line disconnected.

Basically the "tape sense" line could be skipped as well. The project would work but it would be less user friendly. The only thing it would really hurt would be that to use any of the main buttons on the second datasette, you would have to have pressed one of the main buttons on the first datasette. This is because we just passed the "tape motor" signal straight through the first datasette to the second one; the two are in parallel. The computer will not turn on the "tape motor" line until it gets a signal from the "tape sense" line that says one of the main buttons has been pressed. In this case, either one of them, as we have two separate "tape sense" lines that we are going to also put into parallel.

Remember that tiny little leaf switch underneath the main circuit board? Guess what that was? You betcha, that is the "tape sense" mechanism. On my board there was one blue and one black line running to this tiny leaf switch. The black line ran to the ground plane. The blue line ran directly down the main cable to the computer. Since our second tape drive's (stock) wiring will do the same, it will end up at our connector's pin "F" which is hooked to absolutely nothing at the moment. The computer will never know a button is pressed on the second datasette unless we hook something up to handle it. We want the first datasette to pass the second datasette's "tape sense" signal on undisturbed, but we don't want to modify the existing "tape sense" mechanism. We need them in parallel.

Connect one end of a piece of new wire from pin "F" on our new output connector, right at that conveniently open solder point labeled "S" near the top right. We also need to hook the other end of that new wire somewhere. Attach it to the existing blue wire that leads down the first datasette's main cable and on to the computer itself. The blue stripe is nothing but a quick way to indicate that this wire goes from "S" to the same place that those two wires went; under the circuit board, through that little hole up top.

Just be very careful of a few things. When you cut the wire to length, make sure it is long enough to get to where it needs to go without undue stress or stretching. The other wires were all solidly attached to an unmoving object; the PC board. This one is not.

Whatever you do, be very, very careful of excess heat from soldering to the leaf switch. The switch's tiny housing is plastic. Plastic melts with undue heat. Your "tape sense" will not sense anything if it is all broken, warped or otherwise damaged. I suggest that you pre-tin the lead on your new wire, mock it up in place, clip it gently to the existing with an alligator clip to hold them steady while you solder and so on. With the wire lead right where it is physically going to go and pre-tinned with a thin solder coating, it should not take but a half second of soldering iron application to make a good connection. A tiny dab of solder may help if you are worried about cold solder joints.

Modifying the plastic housing

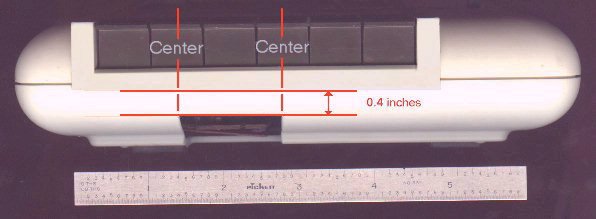

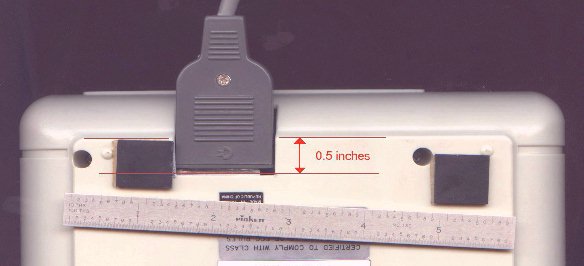

You have to cut a hole in the plastic case of your modified datasette for the second one to be able to plug into the first one. I scanned my own prototype model's case in and added a few helpful dimensions to show you where the hole should be cut. Remember that there are other models out there with different circuit boards! My advice is for you to actually get this far into the process before you just start cutting holes at random!

With that said, here is the front of my drive and the bottom of my drive. The curvature in the picture of the front of my drive is sort of an optical illusion; the hole is cut square. To cut my hole, I used a plastic cutting blade in a dremel; like a circular saw. Other ways would work just as well, if a bit slower. The dimensions I listed there are approximate but close. If you are worried about neatness then I would suggest you cut the hole a little too small at first, on purpose. You can always trim things up a bit with a file, later on.

That's it! Put it all back together and enjoy!

Theory of operation

If you look inside a datasette, you will see there is a connector that is identical to the one used on the computer's datasette port. In other words, a second datasette will plug into the first one; the connector is already there. Unfortunately, the signals on that internal port do not even come close to being what or where they are expected to be.

This leads me to believe the original purpose of the internal connector was a factory testing device, probably used for quality control testing before it left the factory. None of the service schematics I've seen on the net make any reference to technicians in the field doing anything with this connector. But it is there. We can put it to good use.

If you take a look at the schematics for a Commodore Vic20 or a C64, you will see that the datasette port has a read and a write line. They are electrically inverted from one another. If you look at schematics for the internals of a datasette, you will see that they send the very small electrical signal that was read directly off of the tape itself, first to a series of amps and then through multiple stages of inversion circuitry. When the signal leaves the datasette going towards the computer it is definitely a digital and not an analog signal. Likewise, the computer sends its signals to the datasette in digital form.

What this modification does is trick a second datasette into thinking it is getting its signal from the computer, in pure digital form. It likes the signal just fine and it records what it is being sent, as it was designed to. The first datasette has been modified to send that inverted signal to the second datasette, as well as sending it normally to the computer.

In theory, there are three main changes to the modified datasette. The unused internal connector is electrically removed from the rest of the circuitry inside the datasette. In its original state, every single one of the six lines there is totally wrong. The six cut traces and the jumper wires fix this; to put power and ground where they belong, for instance.

Simply put, the second thing that is done is that the output line (that normally goes from a datasette to the computer) is instead routed to the second datasette's input line. This makes the second datasette think it is having a program sent to it from the computer.

The third thing that is done works with the second thing, above. This new signal line we are making needs its signal to be electrically inverted or the modification will not work.

The standard way would be to add an inverter chip to the existing circuitry. However, a close reading of the service schematics of the various datasette models show that the second-to-last inversion stage does produce a strong enough and well-shaped enough signal to be useful for our purposes. Instead of feeding the very last stage's output to the second datasette after inverting it separately, we simply take the already inverted signal from one stage back and we route that to our newly added "daisy chain" tape port. We leave the last stage's signal alone, so that the modified datasette still works as designed.

Our little modification adds a useful feature, while taking none away. It adds no new circuitry to speak of, so the modified datasette draws no additional power. (A second datasette plugged in will draw power, of course; that goes without saying.) And the modification is easier and cheaper to do, because nothing is really added. Very nice!

Labeling your finished project

I could not resist this one final touch... here is a picture of the front face plate area of a standard C2N datasette. What I did was scan that in, touch up a few scratches and such, then added some brief instructions. In other words, if you have a really nice printer (I'm beginning to love my new Lexmark 5700 color inkjet!) you can print out a label on "sticker paper" and put it over the top of the face plate area on your datasette project. It just looks a little better, in my opinion. Plus it does not hurt to have instructions handy!

While this label was designed to go on the top front portion of a datasette, you can trim the printed sticker down a bit, and put it on the bottom of the datasette, if you would rather leave the top surfaces of your datasette the way Commodore made them. ;-) I kind of like the early model's less conservative graphics design, hence the dual usage.

Some general tips on this sort of thing....

If you do not own a printer yourself, you may still be able to do this part of the project. What you can do is have your local copy shop download the label image and print it out for you. Load this page then right-click on this image.

(If you point them to these instructions, they can likely figure out what you want. Don't forget to tell them you need the final printed image sized at 1.22 by 4.75 inches! If you have access to one, some copy shops let you rent a computer/printer by the hour.)

The sticker paper I am referring to here is basically one 8.5 " by 11" sheet of plain label paper. (There are no die-cut shapes on it; the entire sheet is one big uncut label.) It is great stuff for projects like these. With a little imagination, you can even create your own custom label artwork for just about any video game system's cartridges. Lots of fun!

By the way, if you can't find this elsewhere, check your local copy shop. They will probably stare at you a bit, but may gladly sell you as few or as many blank sheets as you want. If you have a choice of sticker papers, just be aware that there are quality ranges, same as any other printer paper. (Yes, photo-type sticker paper does exist.)

You may want to experiment with a paper-only test label at first, before you "waste" a bunch of sticker paper, trying to get everything right. The final print size I used for my image was 1.22 inches tall by 4.75 inches wide. That seemed to work out pretty well for this project. The image is cropped so that it is maybe 1/16" smaller per side than the available space on the front of the datasette itself. This is so no edges stick out very far. Stickers in general tend to start peeling up and looking bad, when too close to edges.

Not every printer will do it, but if yours will feed non-standard sized papers through it without any problems, you can get away with cutting the sheets of sticker paper into thirds, to use less paper per printing job. Other sizes are possible, of course, but so far I am finding that most of the projects I'm currently working on "like" a paper size of 8.5 inches by 3.67 inches. (In other words, 11 inches divided by three separate sheets.)

I experiment till the printed image looks like I want it to, on normal paper. Then I just rotate the image itself 90 degrees, in my graphics program. I tell my page setup window that I want the image to start in the top left corner of the page. (With maybe a 0.5 inch border on top and left sides.) Then I feed the 1/3 sheets in, printing the image sideways. For the Atari 2600 label project, I got ten end labels or two main labels per 1/3 sheet.

Just for what it is worth; the graphics program I use is freely downloadable shareware. If you have an IBM compatible, use a search engine to find a copy of "Paint Shop Pro".

If you have access to one, you can use a laminating machine on the front surface of the label, to give it a protective coating. (Some copy shops may offer this as a service.) I use the thin film stuff myself; a local school supply house offers a do-it-yourself service to local teachers and the public. Basically, in my case, they have a machine that heats up some special clear plastic which bonds to paper. You put your item inside a folded "V" of clear plastic film. Feed it all through the machine. It heats and presses the clear plastic onto the paper. Under normal circumstances you would want both sides of your item to be laminated. You only need the top surface to be laminated, in this case. It may not matter much, however, if you "accidentally" laminate the peel-off back side of the sticker paper. But putting two sheets in, back-to-back, lets me do two at once.

I'll leave you to figure out what is the best method available to you, with whatever laminating services you may have available in your local area. Plan on experimenting.

Worse case, one ridiculously cheap and easy method is to carefully smooth on some clear "shelf paper". It won't look as good, perhaps, but it will protect the label from the inevitable scratches any datasette seems to pick up just from everyday use.

If you plan to add some form of protective coating to your label, do it before you cut the label out, to save yourself some hassle. Easier than trying to line things up perfectly.

The hole in most datasettes is pictured, mostly so you can figure out a way to make a hole in the label itself (before you stick it on) so that you do not cover that hole. One easy way to make room for that hole would be with a standard hole punching device. Note that most of these make holes much larger than the hole you actually need. You may have to experiment a bit, to get everything lined up properly and looking good.